If the LED, inverter or CPU get too hot

Electric current and its hot consequences for your electronic components

Electronic components always get warm - or even hot - during operation due to the electric current flowing through them. The heat is generated by the electrical resistance that exists - to a greater or lesser extent - in all conductive materials within the components. This is a natural process known as Joule heat. As this resistance would only disappear when the component temperature reaches absolute zero (-273.15 °C), the heat problem remains a constant companion to the developer of electronic devices.

With EKL expertise, you have the heat problems of your components under control

It is important to keep the temperature of electronic components within the tolerated range, as excessive heating can shorten their service life and impair their performance. EKL helps you to solve these heat problems efficiently and economically using passive heat sinks, fans, heat pipes, liquid heat sinks or other thermal management techniques.

We have been developing and producing cooling solutions for electronics for 30 years. EKL is therefore your perfect solution partner for regulating the temperature of all components in your electronic device with the help of various manufacturing technologies, including housing fans and housing coolers. The outer walls of housings in particular often offer a large surface area that can be skilfully used for cooling.

We have been developing and producing cooling solutions for electronics for 30 years. EKL is therefore your perfect solution partner for regulating the temperature of all components in your electronic device with the help of various manufacturing technologies, including housing fans and housing coolers. The outer walls of housings in particular often offer a large surface area that can be skilfully used for cooling.

Typical components with overheating problems

CPU gets too hot

The main processor is the brain of a PC or server. Billions of transistors in a processor are activated and deactivated in every work cycle. This process enables the central processing unit (CPU) to carry out the calculations contained in the instructions. To do this, a lot of electricity flows and heat is generated that must be dissipated with performance-appropriate cooling - otherwise the processor gets too hot.

Reasons for inadequate cooling can be, for example, design faults that cause poor air circulation in the housing. The CPU gets hot quickly. If the fan cannot draw in enough air or is blocked, the heat cannot be dissipated effectively. In some cases, forced ventilation is simply not enough and the computer runs hot. Heat pipes or water coolers can then be used to increase the cooling capacity. Particularly in the case of processors that have to work frequently and for long periods in the high-load range, well-founded heat sink calculations and virtual simulations help to determine the required cooling capacity. This enables EKL developers to virtually test various manufacturing processes in order to find the best and most cost-effective alternative for your device.

Reasons for inadequate cooling can be, for example, design faults that cause poor air circulation in the housing. The CPU gets hot quickly. If the fan cannot draw in enough air or is blocked, the heat cannot be dissipated effectively. In some cases, forced ventilation is simply not enough and the computer runs hot. Heat pipes or water coolers can then be used to increase the cooling capacity. Particularly in the case of processors that have to work frequently and for long periods in the high-load range, well-founded heat sink calculations and virtual simulations help to determine the required cooling capacity. This enables EKL developers to virtually test various manufacturing processes in order to find the best and most cost-effective alternative for your device.

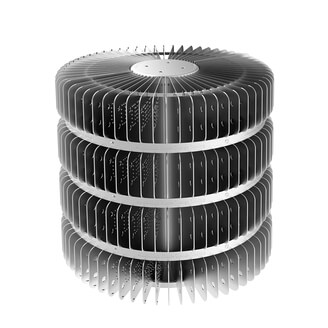

EKL range of CPU coolers

EKL is not only your specialist for customised developments, e.g. for embedded systems tailored to their particular installation situation. Under the EKL and Alpenföhn brands, we have been distributing a very successful standard range of CPU coolers for many years, which reliably prevent your processor from overheating:

CPU coolers from EKL CPU coolers from Alpenföhn®

CPU coolers from EKL CPU coolers from Alpenföhn®

PC case gets hot

A case or computer gets hot when the components are heavily utilised, the cooling is too small or there is an accumulation of dust that obstructs the air flow. Optimising the arrangement of the fans, regular cleaning and avoiding air congestion reduce the risk of the computer overheating.

However, some installation situations do not allow good air circulation to be guaranteed at all times. Alternative cooling solutions such as high-performance heat sinks, heat pipes or liquid coolers should be included in the cooling concept so that the processor heat can still be dissipated effectively.

However, some installation situations do not allow good air circulation to be guaranteed at all times. Alternative cooling solutions such as high-performance heat sinks, heat pipes or liquid coolers should be included in the cooling concept so that the processor heat can still be dissipated effectively.

Inverter gets hot

The power electronics in inverters have to process high voltages and currents, which leads to corresponding power losses and waste heat. At the same time, inverters are often installed outdoors and sometimes have to cope with high ambient temperatures, which reduce the cooling effect.

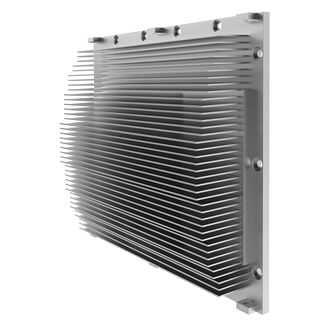

As a rule, attempts are made to create sufficient passive cooling through larger heat sinks and/or more fins in order to increase the surface area for heat dissipation. This passive cooling is practically maintenance-free and therefore a favoured cooling solution against inverter heat.

Fans for inverters significantly increase the cooling capacity through active cooling. The inverter fan blower improves air circulation inside the enclosure, ensures good ventilation and avoids hotspots. The waste heat is dissipated to the outside via the cooling fins. However, active cooling of inverters must be carefully considered, as the fans have a limited service life and must be maintained, cleaned if necessary or replaced if defective.

As a rule, attempts are made to create sufficient passive cooling through larger heat sinks and/or more fins in order to increase the surface area for heat dissipation. This passive cooling is practically maintenance-free and therefore a favoured cooling solution against inverter heat.

Fans for inverters significantly increase the cooling capacity through active cooling. The inverter fan blower improves air circulation inside the enclosure, ensures good ventilation and avoids hotspots. The waste heat is dissipated to the outside via the cooling fins. However, active cooling of inverters must be carefully considered, as the fans have a limited service life and must be maintained, cleaned if necessary or replaced if defective.

Power supply gets hot

It is very important that power supply units are cooled effectively to prevent damage to the electronic components and minimise the risk of fire. Good air circulation in the PC housing, clean fans and unobstructed air ducts help to reduce the operating temperature of the power supply unit. Free air intake and unobstructed air removal extend its service life and help to cool the electronics behind it.

EKL brand fans

EKL brand fans

LED lamp gets hot

LEDs are known for their energy efficiency and low heat generation, but under certain circumstances LEDs can also become too hot. This is because heat loss occurs in the LED chip, which accumulates and needs to be dissipated. Without adequate cooling, the LED becomes hot, which can lead to a reduction in brightness and ultimately to the failure of the LED (so-called "heat death"). Sufficient dimensioning of LED heat sinks, LED fans and, in particular, the right choice of manufacturing technology make a significant contribution to heat dissipation.

Thermal simulation of LED heat sinks

Thermal simulation of LED heat sinks

Battery storage gets hot

Lithium-ion batteries have established themselves as a popular solar storage system in the world of photovoltaics due to their high efficiency and long service life of up to 20 years. The ideal operating temperature is between 10 and 30 degrees Celsius. While the batteries themselves give off very little heat and are easy to cool passively, the solar charge controllers and battery management systems (BMS) place significantly higher demands on efficient cooling. The contained power electronics must monitor and switch high currents, resulting in a correspondingly high power loss. For this reason, EKL offers various cooling solutions for application-specific cooling of these solar charge controllers.

E-car charging station gets hot

The power electronics installed in charging stations, which are responsible for converting and controlling the flow of electricity, generate a lot of heat. These power transistors and thyristors therefore require efficient cooling in order to ensure safe and efficient "refuelling". EKL develops and produces cooling systems specially designed for these applications. Our product range extends from air-cooled high-performance heat sinks to liquid cooling in order to dissipate the heat generated and maintain the performance of the charging station even at high ambient temperatures.

Axle control unit gets hot

In automation technology, axis control - also known as "position control" - is the basis for precise and coordinated movements of machine elements in one or more axes. If many and fast movements are required, these control electronics have a lot to do. The larger the machines and the motor power, the greater the currents to be switched and the greater the power loss. To achieve the ideal of 24/7 machine performance with minimum downtimes in industrial automation, the axis control system must never get hot and fail. With thermal simulations and prototype tests, EKL can develop the ideal cooling solution to keep your position controller within the optimum temperature range, even at peak load and continuous operation.

The economical cooling solution for every heat problem

The requirements in computer and power electronics are constantly increasing, which makes more efficient cooling methods necessary. EKL offers a broad and modern range of technologies to ensure that the components of your device innovations are always optimally cooled.

Our range of manufacturing technologies for cooling solutions include classic profile heat sinks, heat pipes, pressed fins, bonded cooling fins, friction stir welding techniques and skived fin heat sinks. We also offer advanced liquid heat sinks. We are your experienced and dedicated partner to provide the perfect cooling solution for your specific requirements at a reasonable unit cost.

Our range of manufacturing technologies for cooling solutions include classic profile heat sinks, heat pipes, pressed fins, bonded cooling fins, friction stir welding techniques and skived fin heat sinks. We also offer advanced liquid heat sinks. We are your experienced and dedicated partner to provide the perfect cooling solution for your specific requirements at a reasonable unit cost.

Let's talk about your cooling task!

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail

Frank Sichler

Sales Manager

+49 (0)7561 9837-47

f.sichler@ekl-ag.de

Make an appointment Enquiries by e-mail